About us

Nichiwa Inc. specializes in creating high quality precision parts. We are a rapid plastic precision prototype milling company. We have been proudly providing our services to our customers since 1978. Our team is ready to work with you. We provide free quotes within one business day. We are providing services worldwide. Call us today to speak to a customer representative.

Services

ABS/EP/Fluorocarbon resin/GFRP/NW/PA/PBT/PC/PC+GF/ PC+ABS/PE/PEEK/PES/PET/ PF/PI/PMMA/POM/POM+GF/ PP/PPE/PPS/PS/PU/PVC/SW/Urethane resin

(Light Metals)Aluminum/Brass

If you need product with certain material not lised above, let us know! We will figure it out!

Multi-axis machine controlled by our skilled technicians enables quick delivery of high-quality precision parts.

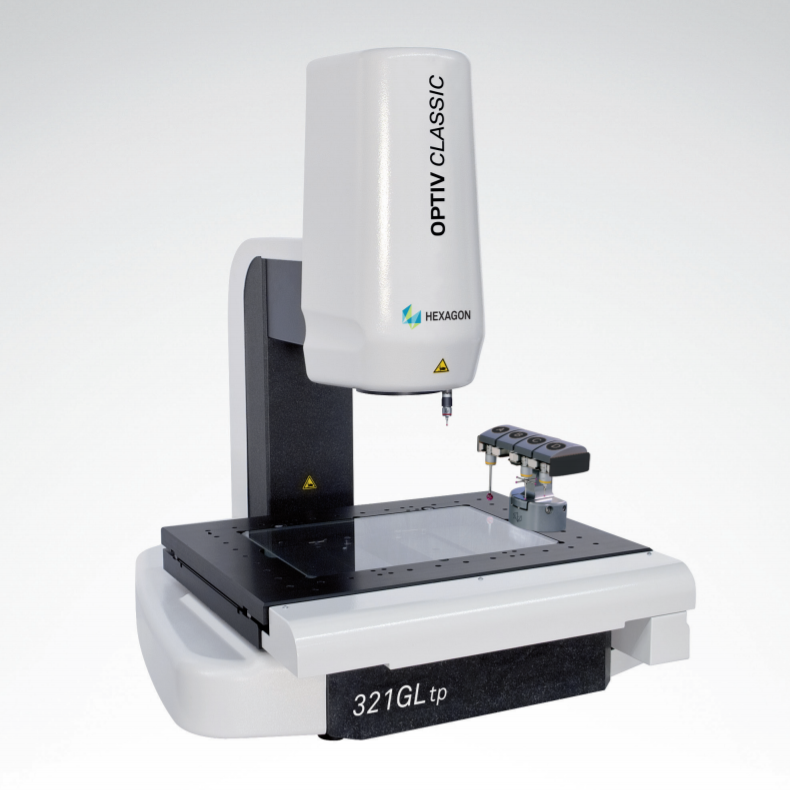

All parts are inspected by precision machines such as OPTIV CLASSIC that efficiently capture and measure data rough optical and tactile measurement in one system. The inspection team creates a measurment routine which the machine automatically executes.

Other machine our company has are video measuring machine and Image dimension measurement system.

-3D CAD model in STEP(*.stp/*.step)

-3D CAD model in IGES(*.igs/*.iges)

-3D CAD model in Unigraphics(*.prt)

-3D CAD model in Parasolid(*.x_t)

-3D CAD model in AutoCAD(*.DXF)

-3D CAD model in CATIA V4 V5 solid

We can also make prototype parts from your CAD drawings.

Our Proccess

Step 1.Estimation

Once we recieved CAD data from our customer, we will make a estimate of the manufacturing based on material size, time and number of parts ordered. We stock more than 25 high grade plastic and light metal materials and each of them have different strength, so we can offer right material for our customer.If you have any query about your project, feel free to contact us on the below information! We will get back to you within 24 hours.

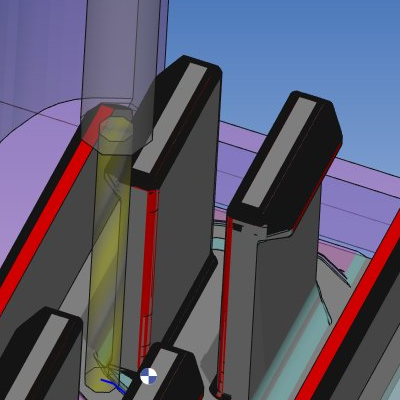

Step 2.Modeling

Based on our customer's CAD data, we will make a program for milling purpose. Same time, we also make sure 3D Solids are okay or broken. We will contact our customer immidiately if we find 3D solids are corrapsed.Therefore, we might edit 3D model for aiming right 3D model shape and tolerance under our customer's approval.

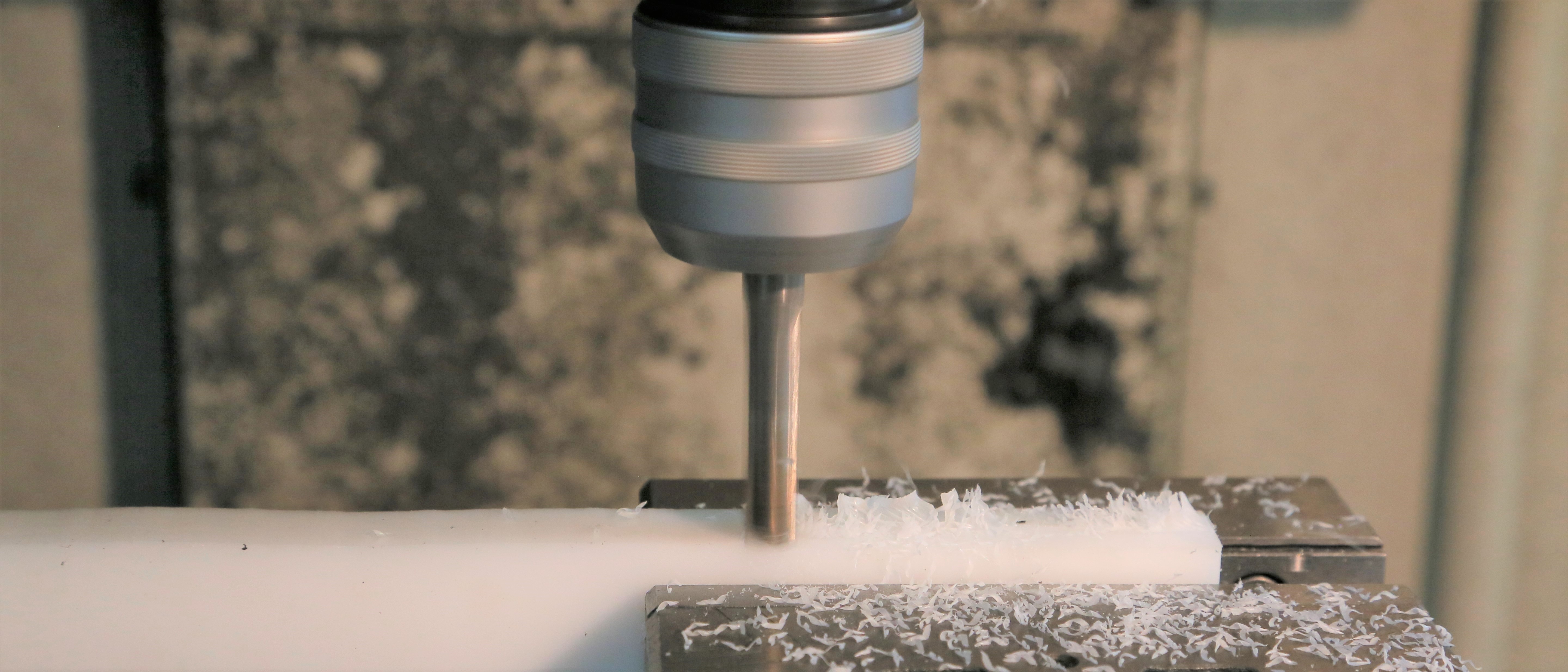

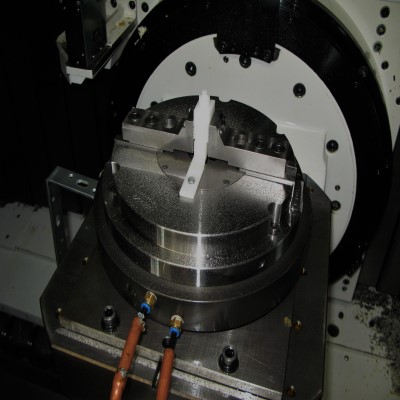

Step 3. Milling

Parts are manufactured with a variety of plastic and Light metal materials. The production of parts are meticulously controlled with the aid of CAM solution software controlling the milling and turning. We currently own 29 machining center include 5-axis machine so, we can mill just 1 piece up to 100. Milling range is 16 inch(length)*12 inch(width)*6 inch(height).

Step 4. Inspection

The finished products are then inspected for quality assurance. Currently, we own 5 different inspection machine, so we are able to use different inspection machine depends on the size of parts and color. Our inspection team works together to probe and dimensioning of parts to assure the exact dimensions requested by the client.

Locations

Contact us today!

phone: +81-142-21-2610 | fax: +81-142-21-2611 | email: info@nichiwainc.com Hours of Operation: Mon-Fri: 9am-5pm in Japan Standard Time